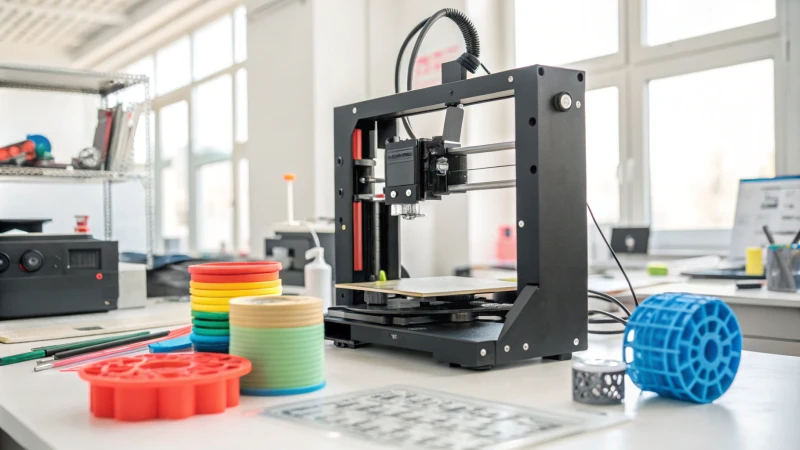

Ever wondered how 3D printing is shaking up the packaging world?

Using 3D printing in packaging design comes with perks like rapid prototyping, allowing for speedy design testing, and custom design capabilities that cater to unique branding needs. It also supports cost-effective small-batch production and speeds up the time-to-market, enhancing supply chain efficiency and boosting ROI.

I remember the first time I held a 3D-printed prototype of our new packaging design. It was like magic seeing our concept come to life in just hours, not weeks. This speed not only saved us time but also allowed us to tweak and perfect the design on the fly. Plus, the ability to customize packaging designs to align with brand identity or special promotions gave us a competitive edge we didn’t have before. It’s these kinds of advantages that make 3D printing an essential part of modern packaging strategies.

3D printing allows for rapid prototyping in packaging design.True

3D printing speeds up prototype creation, enhancing design efficiency.

3D printing increases the cost of small-batch production.False

3D printing reduces costs for small batches by minimizing setup expenses.

How does 3D printing improve packaging design efficiency?

Ever wondered how 3D printing could revolutionize your packaging game? It’s not just a tech buzzword—it’s a game-changer for speed, creativity, and cost-efficiency.

3D printing boosts packaging design efficiency by enabling rapid prototyping, allowing quick design validation, and reducing time-to-market. This technology supports customization, lowers production costs, and optimizes supply chains, ultimately enhancing ROI.

Rapid Prototyping for Swift Validation

One of the most significant advantages of 3D printing in packaging design is its ability to facilitate rapid prototyping1. Traditional methods involve lengthy processes, often requiring weeks to create a single mold. In contrast, 3D printing allows designers to generate prototypes within hours, enabling immediate feedback and iterative adjustments.

- Time Efficiency: Goodbye weeks; hello hours!

- Cost Savings: No more splurging on pricey molds upfront.

| Traditional Method | 3D Printing |

|---|---|

| Weeks for molds | Hours for prototypes |

| High initial cost | Low initial cost |

Customization and Design Flexibility

The ability to create intricate, personalized designs has been a godsend. This enhances brand differentiation2 and appeals to niche markets seeking unique packaging solutions. Remember that time when I needed a unique packaging solution to stand out in a crowded market? 3D printing let me bring those visions to life without breaking the bank or being confined by traditional manufacturing limits.

- Unique Shapes: Tailor designs to mirror brand identity.

- Market Differentiation: Shine with exclusive packaging.

Cost-Effective Small-Batch Production

Without the need for expensive tooling, 3D printing offers a cost-effective solution for small-batch production. This makes it ideal for testing market demand3 and gathering feedback before scaling up production. I recall testing the waters with a new product line—committing to large-scale production felt risky. But 3D printing allowed me to dabble in small-batch production cost-effectively.

- No Mold Costs: Lower financial barriers for small runs.

- Risk Mitigation: Experiment without hefty commitments.

Streamlining the Supply Chain

By facilitating on-demand production, 3D printing significantly streamlines the supply chain4. Its on-demand nature has been a revelation. I remember the days of overstocking and fretting over cash flow. Now, I can produce exactly what’s needed when it’s needed, cutting down on waste and boosting flexibility.

- Agility: Adapt swiftly to market changes.

- Inventory Reduction: Slash storage costs and minimize waste.

Through my journey, I’ve seen how 3D printing does more than just enhance efficiency in packaging design; it aligns with sustainable practices by curbing material waste and promoting the use of recyclable materials. It’s not just about staying ahead—it’s about crafting a future-ready business.

3D printing reduces prototype lead time from weeks to hours.True

3D printing allows for rapid prototyping, reducing time significantly.

Traditional packaging design is more cost-effective than 3D printing.False

3D printing eliminates the need for costly molds, lowering initial costs.

How Can 3D Printing Revolutionize Packaging Customization?

Picture this: you’re holding a perfectly tailored package that tells a story unique to you and your brand. Welcome to the future of packaging with 3D printing!

3D printing transforms packaging customization by offering rapid prototyping, intricate designs, and cost-effective small-batch production. These features allow brands to create unique, personalized packaging that stands out in the market.

How 3D Printing Facilitates Customization

1. Rapid Prototyping: There was a time when I was working late into the night, piecing together a prototype for a new product launch. The pressure to deliver something distinctive was immense. That’s when I discovered the magic of rapid prototyping through 3D printing. Instead of weeks, I could bring my vision to life in mere hours, tweaking designs as needed without the hassle of costly molds.

| Traditional Methods | 3D Printing |

|---|---|

| Weeks to prototype | Hours to prototype |

| High mold costs | No mold required |

This speed not only accelerates the design process but also cuts down time-to-market, helping brands like mine ride the latest trends swiftly and efficiently more insights5.

2. Personalized and Intricate Designs: Then there’s the allure of personalized and intricate designs. Imagine crafting packaging that feels like it belongs solely to your brand—something I’ve found invaluable in industries like luxury cosmetics. Research even shows that personalized packaging can boost market appeal by up to 50% more insights6.

3. Cost-Effectiveness for Small Batches: Cost-effectiveness for small batches was another game-changer. For smaller launches or market tests, where every penny counts, 3D printing offers an affordable alternative to traditional methods market testing strategies7.

The Sustainability Angle

As a business owner committed to sustainability, 3D printing also won me over with its eco-friendly credentials. It reduces waste and allows the use of recyclable materials—crucial for meeting stringent environmental regulations in regions like the EU.

- Material Efficiency: Many 3D printing materials are recyclable.

- Regulatory Compliance: Meets strict environmental standards.

With 3D printing, not only do I achieve remarkable customization, but I also take a step towards a more sustainable future in packaging.

3D printing reduces packaging prototype time to hours.True

3D printing enables rapid prototyping, cutting down the time significantly.

Traditional packaging methods allow for complex geometries.False

Only 3D printing supports intricate designs not possible with traditional methods.

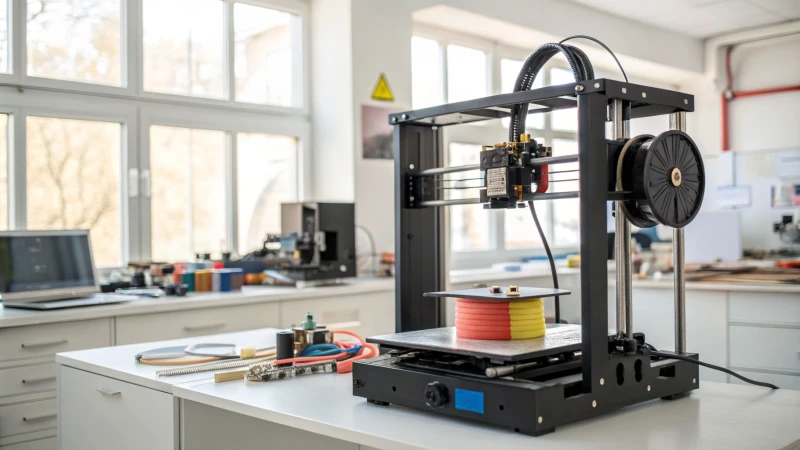

Is 3D Printing Cost-Effective for Small-Batch Production?

Ever wondered if 3D printing is really worth it for small-batch production? I did too! Let’s explore how this tech marvel stacks up against traditional methods.

3D printing can be cost-effective for small-batch production by eliminating tooling costs, reducing waste, and allowing for rapid prototyping. Yet, its overall efficiency hinges on factors like material costs and the scale of production.

Understanding 3D Printing Economics

I remember the first time I stumbled across the idea of using 3D printing for my small-batch productions. It was like discovering a hidden treasure chest in the world of manufacturing! 3D printing, or additive manufacturing, is transforming how we think about creating things. Unlike traditional methods that need pricey molds and tools, 3D printing magically builds objects layer by layer. This approach not only slashes tooling costs but also makes it a dream come true for small-volume orders or custom parts.

| Factor | 3D Printing | Traditional Manufacturing |

|---|---|---|

| Tooling Costs | Low | High |

| Material Waste | Minimal | Significant |

| Customization Flexibility | High | Limited |

Eliminating Tooling Costs

One of the lightbulb moments for me was realizing how 3D printing8 completely sidesteps tooling costs. In traditional setups, those molds can be like financial boulders weighing down a project, especially for smaller runs. Skipping this step could save us thousands per project!

Rapid Prototyping

The other day, I was discussing product designs with a colleague, and we marveled at how 3D printing’s rapid prototyping9 lets us bring ideas to life almost instantly. Instead of waiting weeks, we can whip up prototypes in no time, tweaking and perfecting without the usual delays. It’s like having a magic wand in our toolkit that speeds up our go-to-market time.

Material Costs and Production Scale

But, of course, there are caveats. While 3D printing is a lifesaver in many respects, it’s not always a universal win. Materials for 3D printing can sometimes be pricier than those used in mass production. Plus, as you scale up, traditional methods might start to look more appealing financially due to economies of scale. That’s why it’s crucial to know when to wield this tool.

Considering the Environmental Impact

As someone who cares about sustainability, I find 3D printing’s environmental benefits10 fascinating. It cuts down on waste and often uses recyclable materials, aligning beautifully with eco-friendly goals. However, it’s not without its flaws—energy consumption during the process can be higher than traditional methods. Balancing economic and environmental considerations is key.

In summary, while 3D printing offers significant perks for small-batch production, weighing factors like material costs, production scale, and customization needs is essential to determine its true cost-effectiveness.

3D printing eliminates tooling costs in production.True

3D printing builds objects layer by layer, avoiding expensive molds.

Material costs in 3D printing are always lower than traditional methods.False

While tooling is cheaper, material costs can be higher in 3D printing.

How does 3D printing contribute to sustainable packaging?

Imagine a world where packaging not only protects but also respects the planet. That’s where 3D printing steps in, reshaping how we think about sustainability.

3D printing enhances sustainable packaging by reducing material waste, promoting the use of eco-friendly materials, and facilitating on-demand production, thus minimizing overproduction and inventory excess.

Reducing Material Waste with 3D Printing

One day, as I watched the offcuts from traditional packaging pile up, it hit me: there had to be a better way. That’s when I discovered 3D printing11. Unlike conventional methods that often waste excess materials, 3D printing uses additive techniques, applying material only where needed. This precision drastically cuts down on waste.

Moreover, many printers now even incorporate recycled or biodegradable materials, enhancing their environmental sustainability12. It’s like having a magic wand that not only brings your designs to life but does so responsibly.

Customization and Eco-Friendly Materials

Remember the thrill of getting a custom-made birthday cake? That’s what 3D printing feels like for packaging! This technology allows for bespoke designs without the need for extensive tooling. It not only helps brands stand out but also aligns with sustainable practices13 by using resources wisely.

Designers can play with lighter materials that lower the carbon footprint during shipping. Plus, with innovations in eco-friendly filaments, creating packaging that’s both chic and green is easier than ever.

On-Demand Production and Inventory Reduction

Gone are the days of stockpiling boxes upon boxes in warehouses. With 3D printing, we can produce packaging on-demand. This method means we don’t have to maintain large inventories, helping companies keep a lean supply chain and reducing the environmental impact of overproduction.

For instance, when my company decided to launch a seasonal product line, we used 3D printing to adapt swiftly, avoiding excess stock and staying agile in our supply chain.

Potential for Future Innovations

The future looks bright for 3D printing in packaging. As materials science evolves, we’re likely to see smart materials with features like biodegradability or self-healing properties enter the scene. Imagine packaging that can adapt or repair itself!

By integrating 3D printing with other technologies, brands can approach sustainable packaging holistically, opening doors to exciting opportunities for those committed to environmental responsibility14. Embracing these innovations not only aligns us with a sustainable future but also sets a benchmark for what’s possible in eco-conscious design.

3D printing reduces packaging material waste.True

3D printing uses additive techniques, applying material only where needed.

All 3D printers use biodegradable plastics.False

Not all 3D printers use biodegradable plastics; it varies by model.

Conclusion

3D printing revolutionizes packaging design with rapid prototyping, customization, cost-effective small-batch production, and enhanced sustainability, ultimately improving supply chain efficiency and ROI for businesses.

-

Explore how rapid prototyping with 3D printing accelerates design processes and enhances efficiency. ↩

-

Learn how customization via 3D printing offers brands unique design capabilities and market differentiation. ↩

-

Discover why 3D printing is ideal for cost-effective small-batch production, minimizing investment risks. ↩

-

Understand how 3D printing streamlines supply chains, enhancing agility and inventory management. ↩

-

Discover how rapid prototyping accelerates design processes and reduces time-to-market, crucial for capturing emerging trends. ↩

-

Explore the role of personalized packaging in boosting brand attractiveness and consumer engagement. ↩

-

Understand why small-batch production is essential for market testing without high financial risk. ↩

-

Explore why 3D printing is considered more flexible and cost-effective compared to traditional methods. ↩

-

Understand how rapid prototyping accelerates design processes and reduces time to market. ↩

-

Learn about the sustainability benefits of 3D printing and its role in eco-friendly manufacturing. ↩

-

Understand how additive manufacturing processes minimize waste compared to traditional methods. ↩

-

Discover the types of materials that make 3D printing more sustainable. ↩

-

Learn how tailored packaging solutions can lead to more efficient resource use. ↩

-

Stay informed about upcoming trends and technologies in eco-friendly packaging. ↩