Imagine a world where your favorite cosmetic bottles are as unique as your skincare routine. Welcome to the age of 3D printed glass packaging.

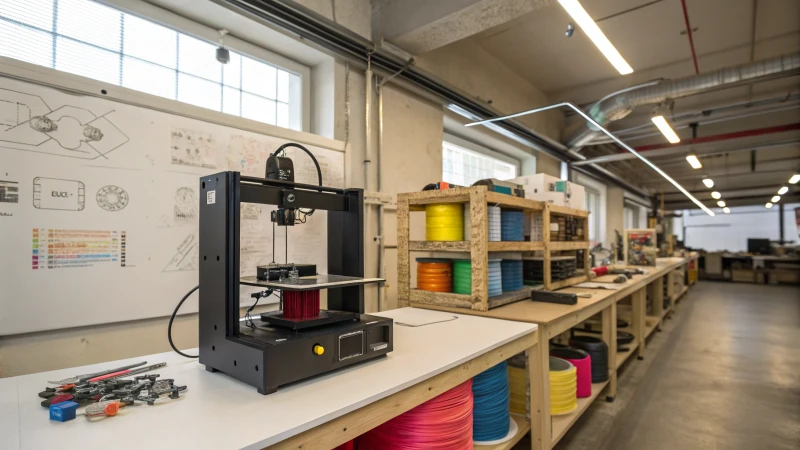

3D printing is transforming the cosmetic industry by enabling fast, affordable customization of glass bottles. This technology solves issues like expensive molds, lengthy production times, and design restrictions, allowing brands to stand out with distinctive packaging while also slashing logistics expenses.

I remember when I first stumbled upon 3D printing technology and realized its potential to shake up the cosmetic packaging game. It was like finding a new tool in my creative toolbox—one that could reshape not just how products looked, but how they connected with consumers. With 3D printing, it’s not just about solving immediate challenges like reducing costs or speeding up production. It’s about pushing the boundaries of what’s possible in design and logistics.

Picture this: You’re launching a limited-edition skincare line, and you need a bottle that embodies your brand’s essence. Traditional methods would have you waiting weeks for molds and production, not to mention the hefty costs. But with 3D printing, you can whip up a prototype in days, tweak it to perfection, and roll out your product just in time for that special launch. This isn’t just a leap forward; it’s a whole new way to future-proof your brand while keeping it fresh and relevant.

The beauty of 3D printing lies in its ability to let your creativity run wild without being tethered to the usual constraints. From intricate embossing to unique bottle shapes, it opens up a world of design possibilities that elevate brand identity. And let’s not forget about the logistical perks—producing closer to market means cutting down on shipping costs and inventory risks, giving you more control over your supply chain.

For anyone in the cosmetics industry, embracing 3D printing isn’t just about keeping up with trends; it’s about leading them, setting new standards for innovation and efficiency. It’s an exciting time to be part of this industry, where technology and creativity blend seamlessly to create something truly extraordinary.

3D printing reduces glass bottle mold costs in cosmetics.Vrai

3D printing eliminates the need for expensive molds, lowering production costs.

3D printing increases logistics costs in cosmetics packaging.Faux

3D printing reduces logistics costs by allowing local, on-demand production.

Why Choose 3D Printed Glass Bottles?

Remember the thrill of creating something unique as a child? 3D printed glass bottles bring that magic to life, offering endless possibilities for customization and innovation. Let’s explore how they’re changing the game.

3D printed glass bottles provide exceptional design flexibility, cost savings, and speedier production. By eliminating costly molds, they allow intricate customizations perfect for brands aiming to stand out efficiently.

Enhanced Design Flexibility

Have you ever stared at a product and thought, "I wish I could make this truly mine"? That’s precisely what 3D printing offers. Traditional glass manufacturing often felt like a straitjacket—creativity squeezed into pre-set molds. But with 3D printing, it’s like handing an artist a blank canvas. You can dream up intricate designs and textures that speak directly to your brand’s soul.

- Custom Textures: Picture running your fingers over a bottle that feels as unique as it looks—custom textures1 make that possible, creating unforgettable tactile experiences that reinforce brand loyalty.

- Unlimited Shapes: From funky curves to elegant lines, the freedom to craft any shape means your packaging can be as memorable as the product it holds.

Cost Reduction

When I first learned about the hefty mold costs in traditional glassmaking, I was taken aback. It’s like paying for a lavish party when you just want a cozy dinner for friends. 3D printing sweeps away those costs, making room for creativity without breaking the bank.

| Cost Aspect | Traditional | 3D Printing |

|---|---|---|

| Mold Creation | High | None |

| Production Flexibility | Limited | High |

| Inventory Risk | High | Low |

- Small-Batch Production: Imagine having the flexibility to produce just what you need without worrying about inventory risk2 or waste. It aligns perfectly with sustainable practices.

Rapid Prototyping and Production

I remember the anxious wait for prototypes in my early days—weeks felt like eternity. With 3D printing, those days are gone. It’s like having a magic wand to create prototypes in days instead of weeks.

- Speed to Market: This nimbleness lets brands ride the wave of trends without missing a beat.

- Real-Time Adjustments: Need to tweak a design? It’s as easy as hitting "edit" on a document—no new molds required.

Sustainability and Efficiency

In my journey, embracing sustainability has become more than a choice; it’s a responsibility. 3D printed glass bottles not only cut down on waste but also promote local production, minimizing carbon footprints.

- Material Efficiency: Thanks to innovative materials3, thinner yet sturdy bottles are possible, using fewer resources without sacrificing quality.

- Local Production: Producing closer to home reduces shipping and supports greener supply chains.

In essence, 3D printed glass bottles aren’t just about staying ahead—they’re about setting new standards in customization, efficiency, and sustainability. They’re rewriting the rules and offering fresh solutions for brands ready to embrace the future.

3D printing reduces glass bottle mold costs to zero.Vrai

3D printing eliminates the need for costly molds, reducing expenses.

Traditional glass bottles allow more design flexibility than 3D printed ones.Faux

3D printing offers greater design flexibility with complex geometries.

How Does 3D Printing Reduce Costs and Lead Times in Packaging?

3D printing isn’t just a tech buzzword—it’s a game-changer in packaging, slashing costs and speeding up timelines. Discover how it reshapes production, bringing unprecedented flexibility and efficiency.

3D printing revolutionizes packaging by removing the need for molds, enabling on-demand production, and facilitating complex designs, thereby cutting costs and lead times while enhancing customization and efficiency.

Eliminating Mold Costs and Lead Times

Back when I first stepped into the world of packaging, I was blown away by how much time and money went into creating molds. Weeks could go by just waiting for a single mold to be perfected before we could even begin production. I remember thinking there had to be a better way—and then came 3D printing. Imagine the relief of skipping the mold-making phase entirely. With 3D printing, we can jump straight from a finalized design to production, saving those weeks and the costs associated with mold creation4.

| Process | Traditional | 3D Printing |

|---|---|---|

| Mold Creation | 4-6 weeks | Not required |

| Design Adjustments | Additional delays | Immediate adjustments |

| Production Start Time | After mold completion | Post-design finalization |

Enabling On-Demand Production

There’s something incredibly liberating about producing exactly what you need, when you need it. It reminds me of a time I had to deal with leftover seasonal stock that was piling up in storage—a costly mistake. 3D printing puts an end to such headaches. We can now produce smaller batches on demand, keeping inventory lean and agile, perfectly tailored to current market needs.

This approach reduces inventory costs5 by minimizing overproduction and storage needs. Companies can respond to market demands swiftly without the pressure of maintaining large inventories.

Facilitating Complex Design Customizations

One of my favorite aspects of 3D printing is the design freedom it offers. I recall a project where we needed intricate textures and complex geometries—something traditional methods couldn’t handle without significant compromises. 3D printing turned that challenge into an opportunity.

For brands aiming to stand out in the market, this technology enables true customization6 of packaging that resonates with consumers, enhancing brand identity and appeal.

Market Adaptability and Responsiveness

In our ever-evolving market landscape, the ability to adapt quickly is invaluable. I’ve learned this firsthand while scrambling to meet changing consumer demands. 3D printing empowers us to pivot swiftly, making rapid prototyping and design adjustments a breeze.

By reducing lead times and enabling rapid prototyping, companies can bring new products to market faster than ever before. This adaptability means products hit the shelves faster, keeping us ahead in fast-paced industries like cosmetics or electronics.

Adopting 3D printing technology has been like unlocking a new realm of possibilities—streamlining costs, shortening lead times, and boosting customization capabilities. It’s not just about staying competitive; it’s about setting new standards in packaging efficiency and innovation.

3D printing eliminates the need for molds in packaging.Vrai

3D printing bypasses mold creation, reducing costs and lead times.

Traditional packaging methods are faster than 3D printing.Faux

Traditional methods require mold creation, causing significant delays.

How Can Brands Achieve Customization with 3D Printing?

Have you ever wondered how 3D printing could revolutionize customization for brands?

Brands can customize with 3D printing by creating intricate designs, producing small batches efficiently, and quickly responding to market demands. This technology enhances product differentiation and streamlines production processes.

Leveraging Intricate Designs

When I first learned about the possibilities of 3D printing, it was like opening a door to a world where creativity knows no bounds. Picture this: you’re a luxury watchmaker, and thanks to 3D printing, you can now create watch dials with intricate patterns7 that were once only dreams on paper. It’s a game-changer, allowing us to break away from traditional design limitations.

Rapid Prototyping and Testing

One of the most exhilarating moments in product development is witnessing your concept come to life. With 3D printing, this process is not only faster but also far more exciting. I remember the first time we used rapid prototyping; we could test various elements of our design within days instead of months. This speed of innovation meant we could reduce time-to-market and adapt quickly to consumer feedback.

Small-Batch Production Efficiency

In my experience, traditional manufacturing often felt like trying to turn a cruise ship around in a pond—slow and cumbersome. But with 3D printing, creating limited-edition products or testing new market ideas has become so much simpler. Just like boutique chocolate makers who craft custom molds for special events or promotional campaigns8, we can produce small batches without the burden of high costs.

Responsive Market Adaptation

I’ve seen firsthand how quickly consumer trends can change, and staying ahead of the curve is crucial. 3D printing allows us to pivot rapidly. Whether it’s a seasonal item or a trending design, we can adapt without missing a beat, ensuring that our products meet customer expectations9.

| Benefits of 3D Printing | Description |

|---|---|

| Design Flexibility | Ability to create complex, customized designs without traditional limitations. |

| Cost Efficiency | Eliminates the need for expensive molds, allowing small-batch production. |

| Speed | Quick turnaround from concept to production, enhancing innovation cycles. |

| Adaptability | Easily adjust designs to align with market trends and consumer preferences. |

Enhancing Brand Differentiation

Standing out in today’s crowded market is no small feat. But with 3D printing, we’ve found a way to make our products truly unique. It’s not just about aesthetics; it’s about creating an emotional connection with consumers through distinctive customization10. This has fostered deeper brand loyalty and positioned us as leaders in our niche.

3D printing allows for cost-efficient small-batch production.Vrai

3D printing eliminates the need for expensive molds, enabling small-batch production.

Traditional manufacturing is faster than 3D printing.Faux

3D printing offers quick turnaround from concept to production, enhancing speed.

How Does 3D Printing Boost Supply Chain Efficiency in Cosmetics?

Ever wondered how 3D printing is shaking up the cosmetics world? Let me share with you how this innovation is changing the game for supply chains in ways I never imagined.

3D printing enhances supply chain efficiency in cosmetics by enabling rapid prototyping, reducing lead times, and minimizing costs. It allows for on-demand production and customization, streamlining operations and improving responsiveness to market changes.

Rapid Prototyping and Production

I remember the first time I encountered 3D printing in my business. It was like magic—ideas that once took months to bring to life were suddenly tangible in days. Traditional manufacturing often feels like navigating a maze with its long lead times for mold creation and mass production demands. But with 3D printing technology11, cosmetics companies can quickly prototype new designs, cutting the time from concept to market drastically. This speed lets brands like ours respond rapidly to consumer trends and launch new products without the usual delays.

Cost Efficiency

I’ll never forget the relief of discovering 3D printing’s cost-saving potential. Previously, the mold costs alone could sink a small-batch or limited-edition project before it even started. With 3D printing, we waved goodbye to these expenses. This technology lets us adjust production quantities without the financial burden of overproduction. It’s a game-changer for us, especially when experimenting with new designs.

| Aspect | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Lead Time | Weeks to months | Days to weeks |

| Mold Costs | High | None |

| Flexibility | Low | High |

Customization and Design Flexibility

One of my favorite aspects of 3D printing12 is the design freedom it offers. Traditional methods limit us with molds, but now, we can create intricate designs and personalized packaging that truly reflect our brand’s identity. This not only enhances brand recognition but also improves consumer engagement by offering tailored products that align with individual preferences.

On-Demand Production and Inventory Management

Managing inventory used to be a nightmare of guesswork and risks. With on-demand production through 3D printing, those days are behind us. Establishing local 3D printing facilities has helped cut down shipping times and costs while keeping our supply chain agile enough to adapt swiftly to changing demands.

| Benefit | Traditional Approach | 3D Printing Approach |

|---|---|---|

| Inventory Risk | High due to bulk production | Low with on-demand flexibility |

| Shipping Costs | Higher with long-distance logistics | Lower with local production |

Enhancing Sustainability and Reducing Waste

Sustainability has always been a core value for me. 3D printing13 aligns perfectly with this by reducing material waste and promoting efficient use of resources. With precise material usage and the potential for biodegradable or recycled materials, we’re not just advancing our business but also contributing positively to the planet.

Embracing 3D printing technology in cosmetics has provided us not only operational advantages but also a way to align with broader market trends towards sustainability and personalization. It’s not just about keeping up with the competition; it’s about leading the way into a more innovative future.

3D printing eliminates mold costs in cosmetics production.Vrai

3D printing requires no molds, reducing costs for small-batch items.

Traditional manufacturing allows for greater design flexibility than 3D printing.Faux

3D printing offers more intricate and customizable designs than traditional methods.

Conclusion

3D printing is revolutionizing cosmetic packaging by enabling rapid, cost-effective customization of glass bottles, enhancing design flexibility, reducing lead times, and improving supply chain efficiency.

-

Discover how custom textures can improve brand recognition and customer engagement by offering unique tactile experiences. ↩

-

Learn how small-batch production minimizes waste and aligns with sustainable practices while providing flexibility. ↩

-

Explore advancements in materials that make glass bottles thinner yet more durable, enhancing sustainability. ↩

-

Learn how 3D printing removes the need for costly molds, saving time and money in packaging production. ↩

-

Explore how on-demand production reduces inventory costs and enhances flexibility in meeting market demands. ↩

-

Discover the unique design possibilities enabled by 3D printing that enhance product appeal and brand identity. ↩

-

Explore how luxury watchmakers leverage 3D printing for intricate design patterns. ↩

-

Discover how custom molds are used in promotional chocolate products. ↩

-

Understand how brands adapt swiftly to market demands with 3D printing. ↩

-

See how brands achieve unique market positioning through 3D printed customization. ↩

-

Discover how 3D printing accelerates product development by enabling rapid prototyping and faster design iterations. ↩

-

Learn about the advantages of customization in 3D printed packaging, including enhanced brand recognition and consumer engagement. ↩

-

Explore how 3D printing contributes to sustainability by reducing waste and utilizing eco-friendly materials. ↩