Transporting glass containers without leaks feels like a high-stakes game.

To keep glass containers leak-proof during transport, I individually wrap them with bubble wrap, use top-notch liners like silicone, and run both pressure and vibration tests. These steps ensure everything stays sealed tight.

I remember the first time I shipped a batch of essential oil bottles. The anxiety was real, imagining precious oils seeping out during their journey. Over time, I learned the art of wrapping each bottle like a cherished gift, ensuring that the right liners are in place to seal even the tiniest gaps. With the added reassurance of rigorous testing, I found peace of mind knowing my products would arrive intact and ready to wow my customers.

Bubble wrap is sufficient for leak-proofing glass containers.Faux

Bubble wrap protects against breakage, not leaks. Liners prevent leaks.

Silicone liners help prevent leaks in glass containers.Vrai

Silicone liners create a seal, preventing liquid from escaping.

What Materials Are Best for Sealing Glass Containers?

Ever wondered what it takes to keep your favorite skincare products fresh and leak-proof?

The best materials for sealing glass containers include silicone liners, PTFE (Teflon) liners, and aluminum foil seals. Silicone offers heat and corrosion resistance, PTFE is excellent for chemical resistance, and aluminum foil prevents evaporation, making each ideal for different applications.

Silicone Liners: Versatility and Durability

Silicone liners quickly became my go-to choice in the world of cosmetic packaging. They’re a dream for anyone looking to seal products that might encounter heat. Think about your favorite face cream that’s been sitting on your bathroom shelf, enduring the steam from daily showers. Silicone liners are like the unsung heroes, ensuring that the freshness and integrity of the product remain intact.

| Feature | Benefit |

|---|---|

| Heat Resistant | Ideal for products exposed to heat |

| Flexible | Ensures a tight seal |

| Durable | Long-lasting performance |

PTFE (Teflon) Liners: Chemical Resistance

In my early days, I had a client who was developing a line of potent skincare serums. They needed something that could withstand the chemical onslaught of their product’s active ingredients. PTFE liners came to the rescue! These liners don’t just hold up; they thrive in environments where others would falter.

For example, highly corrosive substances1 can compromise less resistant materials, but PTFE maintains its integrity, ensuring a safe and effective seal.

Aluminum Foil Seals: Anti-Evaporation Properties

Then there’s aluminum foil seals. Picture this: you’re crafting a delicate perfume, rich in volatile oils that could evaporate faster than you can say "aromatic bliss." Aluminum foil seals are like a safety net, catching all those precious molecules before they can escape into thin air.

Studies show that aluminum foil can reduce evaporation2 by up to 30%, which is a big win when you’re preserving essential oils or creating that perfect scent.

Comparative Analysis of Sealing Materials

Choosing the right sealing material isn’t just about function—it’s about finding that perfect balance between what your product needs and how you want it to perform. Each material has its own strengths, and matching them with your product type is key to ensuring everything stays fresh and functional.

| Matériau | Best Use Cases | Key Properties |

|---|---|---|

| Silicone | Skincare, cosmetics | Heat resistance, flexible |

| PTFE | Chemical storage | Chemical resistance |

| Aluminum Foil | Alcohol-based, perfumes | Anti-evaporation |

And trust me, there’s nothing more satisfying than knowing you’ve got the right seal for your precious creations.

Silicone liners are best for high-end skincare products.Vrai

Silicone's heat resistance and flexibility make it ideal for skincare.

PTFE liners are ineffective against acidic components.Faux

PTFE offers superior chemical resistance, ideal for acidic contents.

How Does Content Type Affect Leak Prevention?

Ever wondered how the type of content affects leak prevention? Dive in to uncover the secrets that keep both physical and digital worlds leak-free.

Content type plays a pivotal role in leak prevention by dictating the choice of sealing materials and methods. For example, oily substances require oil-resistant liners, while alcohol-based items need anti-evaporation seals. In digital security, Content-Type headers help prevent data leaks by specifying how browsers should process different file types.

Physical Properties and Leak Prevention

I remember the first time I had to deal with an oily formulation—it was a nightmare. The liquid seeped through everything, ruining the packaging and creating a mess. That’s when I learned the importance of EPE foam liners. They’re like the superheroes of leak prevention for oily liquids. These liners resist oil like nothing else, keeping everything contained without a fuss. And then there’s alcohol-based products. It’s not just about keeping the lid tight; it’s about choosing aluminum foil seals that ward off evaporation. Think of it as putting a shield over your product to keep its essence intact.

| Content Type | Recommended Liner | Key Feature |

|---|---|---|

| Oily | EPE Foam | Oil Resistance |

| Alcohol-Based | Aluminum Foil | Anti-Evaporation |

Chemical Properties’ Role

High-viscosity liquids are another beast altogether. Imagine pouring honey into a bottle—if the threads aren’t perfectly matched, you’re in for a sticky situation. I discovered that precise manufacturing processes, using precision mold processing3, make all the difference. It’s like finding the perfect dance partner; everything just clicks into place without any leaks.

Web Security: Content-Type Headers

Switching gears to web security, the Content-Type header is your best friend in preventing data leaks. It’s like setting up a digital barrier that tells browsers exactly how to handle files, keeping unauthorized eyes out. As part of a broader Content Security Policy4, these headers are essential for managing data flow and shielding against cyber threats.

Industry Practices and Innovations

In places like Europe, they don’t mess around with leak prevention for high-end products like skincare oils. Multi-layer liners are standard, offering top-notch protection by layering materials to stop leaks cold. It’s fascinating how understanding these practices helps businesses align with international standards.

Emerging trends are focusing on dual testing methods, which include negative pressure and shock resistance tests during transportation5. These ensure comprehensive leak prevention during transit, significantly reducing loss during transportation.

By exploring these dimensions, businesses can align their strategies with both market demands and technological advancements.

Oily liquids require EPE foam liners for leak prevention.Vrai

EPE foam liners are oil-resistant, preventing leaks from oily liquids.

Alcohol-based products benefit from plastic seals to prevent leaks.Faux

Alcohol-based products use aluminum foil seals to mitigate evaporation.

Why Is Mold Precision Important for Leak-Proofing?

Have you ever wondered how something as simple as mold design can make or break your product’s leak-proof packaging?

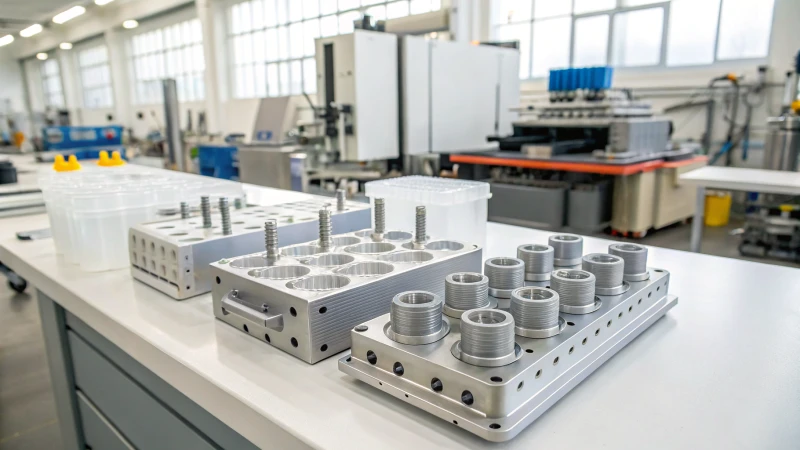

Mold precision is crucial for ensuring leak-proof packaging because it guarantees the perfect alignment and fit of bottle necks and caps, effectively preventing leaks. By minimizing thread deviations, high-precision molds enhance sealing effectiveness for various liquids.

Understanding Mold Precision in Packaging

Picture this: you’re in the middle of a long-awaited trip, and suddenly, the carefully packed shampoo bottle in your suitcase has leaked all over your clothes. Frustrating, right? This is where mold precision comes into play, ensuring that such mishaps are a thing of the past. Mold precision refers to how accurately molds are crafted to produce consistent and high-quality products. When it comes to leak-proof packaging, this means creating bottle necks and threads6 that align perfectly with their caps.

The Impact of Thread Deviations

Imagine the threads on a bottle neck not aligning properly with those on the cap. This misalignment can create gaps, allowing liquids to escape—a nightmare for any traveler or business owner dealing with liquid products. Precision molds ensure that thread deviations remain within acceptable limits (usually ±0.2mm), providing a snug fit that prevents leaks.

Here’s an illustrative table:

| Factor | Acceptable Limit | Impact on Leak-Proofing |

|---|---|---|

| Thread Deviation | ±0.2mm | Prevents leakage |

| Seal Ring Design | Double rings | Enhances sealing strength |

Material Considerations in Mold Design

Each type of liquid demands unique sealing solutions due to varying physical and chemical properties. For instance, oily formulations do well with EPE foam liners because of their oil resistance, while alcohol-based products7 need aluminum foil seals to prevent evaporation. It’s essential that molds accommodate these material specifications to effectively prevent leaks.

The Role of Testing in Leak Prevention

Testing is a critical step in verifying mold precision. I always recommend suppliers conduct negative pressure and vibration tests to mimic real-world conditions that packaging might face during transportation. Negative pressure tests check if seals stay intact under different atmospheric conditions, while vibration tests evaluate the package’s durability against movement and shocks.

Case Study: A Cautionary Tale

There was a North American client who chose a cheaper supplier, thinking it would save money. Unfortunately, they faced a high leakage rate due to poor mold precision—the supplier couldn’t maintain thread accuracy, leading to batch sealing deviations. After switching to a supplier equipped with precision mold processing8 equipment, their leakage rate dropped significantly.

Future Trends in Leak-Proof Packaging

As consumers become more quality-conscious, companies are increasingly demanding comprehensive leak tests before shipping. European and American markets are setting new standards by requiring dual testing protocols, including negative pressure evaluations and ISTA-3A transportation standards.

In summary, mold precision isn’t just about aesthetics or saving costs; it’s crucial for ensuring leak-proof packaging that aligns with industry standards and meets consumer expectations.

Thread deviations of ±0.5mm are acceptable.Faux

Acceptable thread deviation is ±0.2mm, not ±0.5mm, to prevent leaks.

Negative pressure tests assess seal integrity.Vrai

Negative pressure tests ensure seals remain intact under atmospheric changes.

What Are the Latest Testing Standards for Leak Prevention?

Ever found yourself worrying about a product leak at the worst possible time? Dive into the latest testing standards ensuring your peace of mind.

The latest leak prevention standards emphasize advanced testing methods such as negative pressure and vibration resistance. Standards from ASTM and ISO provide detailed guidelines to maintain product integrity across various industries.

Understanding Industry Standards

I remember when I first came across the labyrinth of industry standards; it was like deciphering a new language. Organizations such as ASTM9 and ISO have crafted guidelines that are almost like a safety net for our products. These standards aren’t just about ticking boxes—they ensure our products are safe and effective, especially in sensitive areas like pharmaceuticals and packaging.

| Organization | Standard Type | Key Focus |

|---|---|---|

| ASTM | ASTM F2096 | Bubble emission testing for packaging |

| ISO | ISO 11607 | Packaging for terminally sterilized medical devices |

Advanced Testing Techniques

Negative Pressure Tests

Imagine placing your product in a vacuum to see if it holds its breath—that’s essentially what negative pressure testing is. It’s a vital test to ensure products can survive environmental changes without leaking. Learn more about negative pressure testing10.

Vibration Resistance Tests

I once watched a shipment shake its way across the globe, and it was eye-opening. Vibration tests mimic these journeys to pinpoint seal weaknesses. It’s like stress-testing a friendship to make sure it lasts.

Material Selection in Leak Prevention

Choosing the right materials feels like picking the perfect outfit—essential for leak prevention. Recent trends show the importance of selecting top-notch liners and seals that stand up to both chemical reactions and physical stress. Explore material selection strategies11.

Real-World Applications and Case Studies

Case studies from industries such as food packaging and pharmaceuticals have shown me firsthand how following updated standards can dramatically cut down on leakage issues. There’s a pharmaceutical company that revolutionized its sealing process by using dual-layer seals, slashing leakage rates significantly. Discover more case studies12.

ISO 11607 focuses on food packaging.Faux

ISO 11607 is for packaging of sterilized medical devices, not food.

Vibration resistance tests identify seal weaknesses.Vrai

They simulate transport conditions to detect potential seal failures.

Conclusion

To ensure glass containers are leak-proof during transport, use bubble wrap, silicone liners, and conduct pressure tests. Proper sealing materials and mold precision are crucial for preventing leaks.

-

Learn about PTFE liners’ unmatched chemical resistance, ideal for sealing containers with acidic or corrosive contents. ↩

-

Explore how aluminum foil seals effectively prevent evaporation in alcohol-based products. ↩

-

Precision mold processing equipment is essential for creating exact thread fits, which are crucial in preventing leaks in high-viscosity formulations. ↩

-

Content Security Policy best practices guide the secure handling of data across web platforms, reducing leak risks. ↩

-

Negative pressure tests simulate conditions during transport, ensuring leak-proof packaging and minimizing losses. ↩

-

This link explores how precise mold alignment contributes to effective sealing and leak prevention. ↩

-

Discover which materials are most effective for sealing alcohol-based products. ↩

-

Learn how using advanced mold processing equipment can enhance product quality and reduce leakages. ↩

-

Understand ASTM’s specific guidelines on leak prevention to enhance compliance with industry standards. ↩

-

Negative pressure testing is vital for ensuring seal integrity under environmental changes. ↩

-

Proper material choice is crucial for effective leak prevention, especially in packaging. ↩

-

Case studies provide practical insights into the application of leak prevention standards. ↩