Remember that time you picked a product just because of its stunning packaging? That’s the power of presentation!

Screen printing is your go-to for durable, multi-color designs on cosmetic glass bottles, offering design flexibility. In contrast, hot stamping delivers a luxurious metallic finish that enhances a product’s premium appeal. Your choice hinges on brand needs like cost, design complexity, and the aesthetic you’re aiming for.

I remember when I first started exploring packaging options. It felt like being a kid in a candy store—so many shiny options! Each method seemed to promise something different, yet equally appealing. As I dove deeper into screen printing and hot stamping, I realized that understanding these subtle differences was crucial. Screen printing felt like painting a masterpiece with its durability and vibrant colors, while hot stamping was like adding that final touch of gold leaf—luxurious and eye-catching. Let’s explore these methods further so you can make the best choice for your brand.

Screen printing is less durable than hot stamping.Vals

Screen printing is known for its durability, especially on glass.

Hot stamping offers a more premium look than screen printing.Echt

Hot stamping provides a luxurious metallic finish, enhancing appeal.

How Does Screen Printing Enhance Brand Durability and Design?

Imagine a world where your brand’s design stays vibrant and intact, no matter the wear and tear. That’s the magic of screen printing.

Screen printing enhances brand durability and design by delivering enduring, vibrant graphics that resist fading and wear. It supports intricate, multi-color designs, ensuring a superior brand image on various materials.

The Role of Screen Printing in Brand Durability

You know, when I first ventured into the world of packaging, I was amazed by how screen printing could transform a simple item into a brand ambassador. The durability of screen-printed designs is incredible. The ink binds firmly with materials like glass or fabric—it’s like they’re meant to be together! This bond means less fading, scratching, and peeling, keeping your brand looking as fresh as the day it was made.

| Functie | Benefit |

|---|---|

| Ink Adhesion | Long-lasting prints |

| Scratch Resistance | Preserves brand image integrity |

| UV Stability | Prevents fading under sunlight |

Design Flexibility with Screen Printing

When it comes to design, screen printing feels like having an artist’s palette at your disposal. I recall working on a project where we needed to capture the vibrancy of our logo across various products. Screen printing was a game-changer. It handled the intricate details and vivid colors effortlessly, allowing each product to pop with personality.

- Color Depth: Achieved by layering ink, enhancing vibrancy.

- Detail Precision: Suitable for fine lines and complex patterns.

- Versatility: Works well on diverse materials, from textiles to glass.

Environmental Considerations

I’m also proud of how screen printing aligns with sustainability goals. Many brands, including mine, are turning to eco-friendly inks and recyclable materials. It’s a small change with a big impact—not just on the planet but also on how consumers perceive us. It’s reassuring to know that our environmental efforts resonate with customers who care about green initiatives.

- Eco-Friendly Inks: Options like water-based or plant-based inks reduce emissions.

- Material Compatibility: Suitable for recyclable substrates.

- Consumer Appeal: Aligns with green branding strategies.

For more insights into how screen printing can revolutionize your packaging strategy, consider exploring customized packaging1 options tailored to your brand’s needs. With technological advancements, screen printing continues to evolve, offering innovative solutions for both durability and design excellence.

Discover more about how screen printing can benefit your brand by investigating its adaptability2 in various market segments. The process’s inherent ability to maintain high-quality prints across different materials ensures that it remains a preferred choice for many industries.

Screen printing inks are UV stable.Echt

Screen printing inks prevent fading under sunlight, ensuring durability.

Eco-friendly inks reduce emissions in screen printing.Echt

Using water-based or plant-based inks lowers environmental impact.

Why Is Hot Stamping Considered a Luxury Packaging Solution?

I remember the first time I saw a beautifully stamped package – it was like holding a piece of art. Hot stamping is where luxury meets elegance, making brands shine brighter on the shelves.

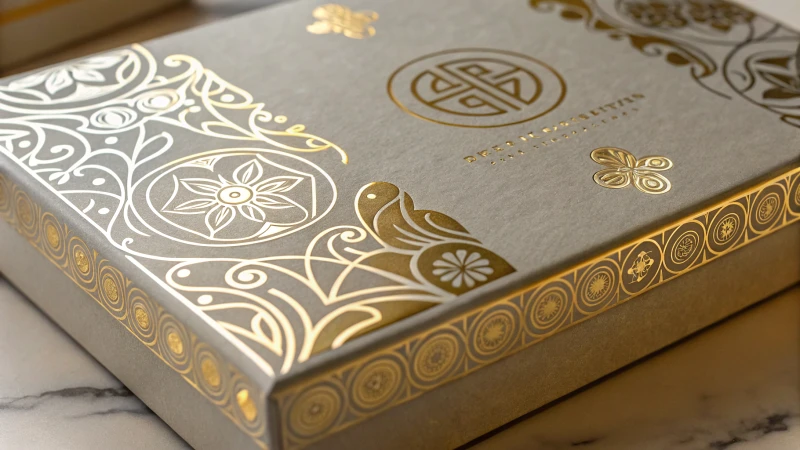

Hot stamping is seen as a luxury packaging solution because it uses metallic foils to craft visually stunning designs that exude elegance and premium quality. Its precise application and wide range of finishes make it perfect for high-end branding.

The Art of Metallic Elegance

Have you ever held a package that just felt luxurious in your hands? That’s the magic of hot stamping. This technique uses a heated die to press metallic or pigmented foil onto packaging materials, creating a glossy, reflective finish that catches the eye. I remember the first time I saw this in action – it was at a trade show, and the packaging seemed to shimmer under the lights. It’s this metallic allure3 that makes hot stamping such a compelling choice for brands wanting to convey an air of luxury, similar to how precious metals catch our attention.

| Functie | Benefit |

|---|---|

| Reflective Finish | Eye-catching and distinctive |

| Metallic Foils | Conveys luxury and elegance |

| Precision Application | Consistent, high-quality results |

Precision and Quality Control

The precision in hot stamping isn’t just about aesthetics; it’s about maintaining a standard of excellence across all products. Imagine walking into a store and seeing your product gleaming perfectly under the lights – that’s the impact hot stamping can have. Using advanced technology4, brands can create intricate designs that elevate their product’s visual appeal, ensuring every package tells the same story of quality and care.

Versatility in Design

What I love about hot stamping is its versatility. It’s not confined to just metallic finishes; you can also use holographic foils to add depth and dimension to your designs. This flexibility opens up endless creative possibilities5, allowing brands to experiment with textures and colors to create something truly unique. For designers like me, it’s an exciting playground for pushing aesthetic boundaries.

Enhancing Brand Perception

There’s something special about a product that feels luxurious before you even open it. The tactile sensation of embossed designs combined with shiny foils leaves a lasting impression. I once received a gift wrapped in hot-stamped paper, and even before seeing what was inside, I felt like I was holding something special. This is why luxury brands invest in high-quality packaging6 – it’s about making products desirable right from the first touch.

Sustainability Considerations

In today’s world, luxury doesn’t have to come at the expense of our planet. I’ve noticed more companies shifting towards eco-friendly options in hot stamping, using sustainable foils that don’t compromise on aesthetics. This evolution reflects a commitment to combining opulence with responsibility, appealing to consumers who care about both style and sustainability. It’s an exciting trend towards sustainable solutions7 that respect our environment while maintaining that high-end look.

Hot stamping uses only metallic foils.Vals

Hot stamping can also use holographic foils, not just metallic ones.

Hot stamping enhances brand perception.Echt

It adds tactile and visual appeal, boosting perceived value and desirability.

How Do Screen Printing and Hot Stamping Affect Costs?

Navigating the world of printing methods feels like walking through a maze of cost considerations, each path offering a unique twist.

Screen printing is budget-friendly for large runs due to lower per-unit costs, whereas hot stamping offers upscale finishes but at a higher price per piece.

When I first dived into the world of printing for my business, I felt overwhelmed by the sheer variety of choices. But, over time, I realized that understanding the financial nuances of screen printing versus hot stamping could save me from a lot of unnecessary headaches.

Cost Analysis of Screen Printing

Screen printing involves using a mesh screen to apply ink onto a surface. It’s a cost-effective choice for bulk production due to its low per-unit price. However, initial setup costs for screen creation and machine setup can be significant.

| Factor | Screen Printing |

|---|---|

| Setup Costs | High due to screen preparation |

| Per Unit Cost | Decreases with volume |

| Design Complexity | Flexible for multi-color patterns |

The efficiency of screen printing is maximized8 when used for large-scale production runs, making it ideal for businesses focusing on economies of scale. This method allows for vibrant, detailed designs but requires a substantial upfront investment in equipment.

Exploring Hot Stamping Expenses

Hot stamping uses a heated die to transfer metallic foil onto surfaces, creating luxurious effects. The cost implications here are different from screen printing due to the materials involved and the precision required.

| Factor | Hot Stamping |

|---|---|

| Setup Costs | Relatively lower but depends on die customization |

| Per Unit Cost | Higher due to material costs |

| Material Use | Metallic foils, often costly |

Hot stamping is suitable for small-batch, high-end products where aesthetic appeal9 is paramount. While the setup may be less complex than screen printing, the cost per unit remains high due to premium materials like metallic foils.

Material Costs and Alternatives

Both methods involve specific material costs that can influence overall expenses. In screen printing, the type of ink—such as water-based or plastisol—can affect pricing. For hot stamping, the choice between traditional metallic foils and innovative substitutes10 like thin film metal foil can provide cost-saving opportunities.

Choosing the right materials can sway costs significantly. I’ve experimented with various inks and foils—like opting for water-based inks or innovative metallic substitutes—to strike a balance between cost and quality. These choices not only influence budget planning but also align with sustainability goals.

Impact of Production Volume and Design Complexity

Production volume directly impacts cost efficiency in both methods. Screen printing becomes more economical as volume increases due to the distribution of setup costs over more units. Conversely, hot stamping maintains a consistent cost per unit regardless of volume but excels in projects requiring high-quality finishes.

Design complexity also plays a role. While screen printing handles intricate multi-color designs well, hot stamping might struggle with elaborate patterns unless additional steps are taken, increasing costs further.

Whenever I tackled intricate designs, screen printing was my go-to; for simpler yet stunning looks, hot stamping stole the show.

Understanding these intricacies lets you tailor your choice to fit budgetary constraints and aesthetic goals effectively.

Screen printing has high setup costs.Echt

Screen preparation and machine setup are costly for screen printing.

Hot stamping is cheaper for large-scale production.Vals

Hot stamping has high per-unit costs due to premium materials.

Which Printing Method Best Aligns with Sustainable Practices?

Ever wonder how your printing choices can make a difference for the planet?

Screen printing and digital printing are among the most sustainable methods. Screen printing uses eco-friendly inks and reusable screens, while digital printing minimizes waste and energy use. Both offer viable green alternatives for businesses.

Understanding Sustainable Printing Practices

To determine which printing method aligns best with sustainable practices, it’s important to examine each method’s environmental impact. Screen printing11 and digital printing stand out for their low ecological footprints.

Screen Printing: A Green Champion?

Imagine a time when I watched artisans craft vibrant designs using screen printing. They explained how water-based and plant-based inks not only brought out vivid colors but also minimized nasty emissions. Plus, those reusable screens? They mean less waste piling up, which is a win in my book. But I’ve learned that this process takes some careful setup—something to think about if you’re dealing with smaller runs or intricate designs.

| Functie | Benefit |

|---|---|

| Water-based inks | Reduced VOC emissions |

| Reusable screens | Lower waste generation |

While screen printing has advantages, it also requires meticulous setup. This aspect might affect its practicality for smaller print runs or intricate designs.

Digital Printing: Efficiency and Sustainability

Then there’s digital printing. I remember chatting with a friend who runs a small print shop and swears by its minimal waste production. No need for printing plates means less material use, and its precision helps avoid overproduction—a great fit for anyone keen on aligning with sustainability goals12. However, my friend also mentioned that the sustainability of this method greatly depends on the energy sources used. Renewable energy can really boost its eco-friendliness.

- No Plates Needed: Cuts down material use significantly.

- Precision: Reduces waste by matching production closely to demand.

Evaluating Other Methods

Let’s not forget offset and flexographic printing. I’ve seen them used in various places, yet they don’t quite match up to the environmental benefits offered by screen and digital methods.

| Method | Key Consideration |

|---|---|

| Offset | High-quality prints but energy-intensive |

| Flexographic | Fast production but uses non-renewable materials |

Choosing the right method isn’t just about the environment; it’s about finding that sweet spot between sustainability, production needs, and business goals. It’s crucial to look beyond just the method—consider the whole supply chain13 involved in your printing operations. And trust me, once you start thinking sustainably, it changes how you see every part of your business.

Screen printing uses water-based inks.Echt

Water-based inks in screen printing reduce VOC emissions, making it eco-friendly.

Digital printing requires printing plates.Vals

Digital printing does not use plates, reducing material use significantly.

Conclusie

Screen printing offers durability and design flexibility for large cosmetic packaging, while hot stamping provides luxurious metallic finishes ideal for premium brands. Choose based on production needs and aesthetics.

-

Explore how customized packaging through screen printing can enhance brand recognition and consumer engagement. ↩

-

Learn how screen printing adapts to different markets and product types, ensuring quality and consistency. ↩

-

Explore how metallic finishes enhance the visual appeal and perceived value of products. ↩

-

Learn about the technologies that ensure consistent quality in hot stamping applications. ↩

-

Discover how designers use hot stamping to innovate and create unique packaging. ↩

-

Understand the impact of premium packaging on consumer perceptions and brand identity. ↩

-

Find out about sustainable alternatives to traditional foils in hot stamping. ↩

-

Discover how screen printing optimizes costs in large production runs. ↩

-

Learn why hot stamping is favored for luxury product finishes. ↩

-

Explore cost-effective alternatives to traditional metallic foils. ↩

-

This link explores how screen printing supports eco-friendly practices through its use of sustainable inks and materials. ↩

-

Learn about digital printing’s efficiency and its role in reducing waste and aligning with sustainable practices. ↩

-

Explore how optimizing the supply chain can further enhance the sustainability of your chosen printing method. ↩